The Real Cost of Ignoring Workplace Safety in Malaysia

The statistics are clear: Ignoring safety hurts your business's bottom line

Although many employers consider workplace safety to be costly, the cost of ignoring it is actually much higher. A business can easily be destroyed by the hidden costs of ignoring safety, which include lost productivity, reputational harm, and legal fines.

Let's examine the actual costs incurred by employers in Malaysia when workplace safety is disregarded.

1. Legal and Regulatory Penalties

Every employer is legally obligated to provide a safe and healthy work environment under Malaysia's Occupational Safety and Health Act (OSHA) 1994.

Noncompliance may result in:

● Fines up to RM500,000 or imprisonment up to 2 years, or both.

● Suspension or shutdown of business operations.

● Heavier penalties for repeated or fatal incidents.

● Neglecting safety isn’t just risky — it’s illegal.

Section | Offense / Breach | Penalty ( Amended 2024) |

|---|---|---|

S15, S16, S17, S18, S18A, S18B | Employer / self-employed / principal fails to carry out statutory duties (safety, health, welfare, risk assessment, etc.) | Fine up to RM 500,000 or imprisonment up to 2 years, or both |

S20, S21 | Designers, manufacturers, suppliers failing duties (e.g. plant / substance safety) | Fine up to RM 200,000 or imprisonment up to 2 years, or both |

S24(1), (2) | Employee fails to comply with general duty (cooperate, use PPE, follow instructions) | Fine up to RM 2,000 or imprisonment up to 3 months, or both |

S27(3) | Discrimination against employees (e.g. removed from danger, reporting safety issues) | Fine up to RM 100,000 or imprisonment up to 1 year, or both |

S29 | Failure of occupier of workplace to comply with duties | Fine up to RM 50,000 or imprisonment up to 6 months, or both |

S29A | Employer fails to appoint Occupational Safety & Health Coordinator (when ≥ 5 employees) | Fine up to RM 50,000 or imprisonment up to 6 months, or both |

S30(4) | Failure to establish Safety & Health Committee (when required, e.g. ≥ 40 employees) | Fine up to RM 100,000 or imprisonment up to 1 year, or both |

S31A(4) | Employer fails to ensure selected employees attend required safety & health training | Fine up to RM 50,000 or imprisonment up to 6 months, or both |

S31B(2) | Person not competent conducting activities under Fifth Schedule (e.g. safety training) | Fine up to RM 100,000 |

S35(3) | Failure to comply with Director General’s order prohibiting use of plant/substance | Fine up to RM 500,000 or imprisonment up to 2 years, or both |

S48 / S49(2) | Failure to comply with improvement or prohibition notices | Fine up to RM 500,000 or imprisonment up to 2 years, or both; continuing offence: RM 2,000 per day |

S51 (General penalty) | Contravention of OSHA where no specific penalty is provided | Fine up to RM 100,000 or imprisonment up to 1 year, or both; continuing offence: RM 2,000 per day |

S67(3) | Breach of duty of confidentiality | Fine up to RM 100,000 or imprisonment up to 2 years, or both |

OSHA Amendment 2024

2. Compensation and Medical Expenses

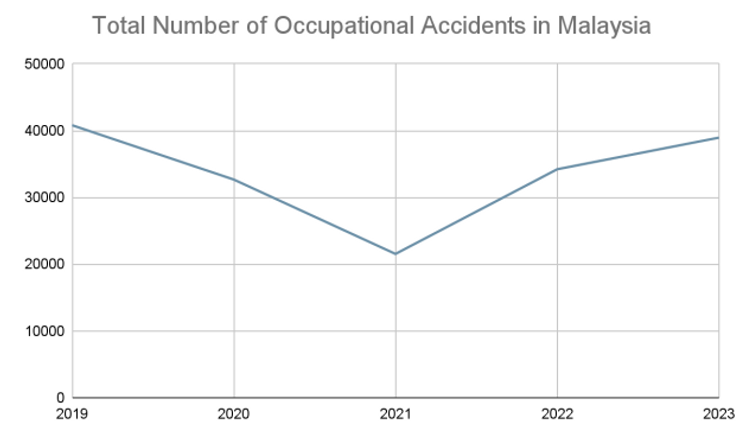

Employers are responsible for both direct and indirect costs in the event of an accident. While SOCSO may pay compensation, employers are still responsible for medical expenses, overtime compensation for replacements, and lost productivity. According to an DOSH study, the number of reported occupational accident has been on steady increase since 2023. Therefore, this also increase the cost of medical expense.

Source: BIG DATA ANALYTICS - NATIONAL OCCUPATIONAL INJURY AND DISEASE STATISTICS 2023

Not including harm to one's reputation, a single death can cost about RM1.2 million.

3. Damage to Property and Equipment

Raw materials, automobiles, and machinery can sustain significant damage in accidents. If negligence is proven, insurance might not cover all losses, and the business would be responsible for paying for replacements or repairs.

An entire production line can be stopped by one moment of negligence.

4. Productivity Loss and Employee Turnover

The effects of workplace accidents extend beyond the immediate injuries sustained; they affect the entire operation of the company. Accidents won't be a "if," but "when" if employers don't make sure all workers follow safety protocols. Injuries, losses, and irreparable harm to operations and trust are the inevitable outcomes.

● Injured workers mean reduced efficiency.

● Staff morale drops due to fear and stress.

● Skilled workers may resign, leading to more recruitment and training costs.

● Downtime means deadlines missed and clients lost.

5. Rising Insurance Premiums and Legal Costs

Your insurance rates and legal risks go up if you have a bad safety record. If the insurer determines that your workplace is unsafe, you may even find it difficult to renew coverage. Additionally, legal defense costs can amount to tens of thousands of ringgit if a lawsuit is filed after a death or serious injury. Litigation is always more expensive than prevention.

6. Reputational and Business Damage

In the connected world of today, bad news spreads quickly. One significant mishap can harm the reputation of your company, making it more difficult to:

● Win new contracts

● Attract skilled talent

● Retain existing clients

It takes years to build a reputation, but it can be destroyed in an instant.

7. The Overall Cost to Employers

Type of Cost | Example | Estimated Price (RM) |

|---|---|---|

Legal Fines | OSHA violations | Up to 500,000 |

Compensation & Medical | Injuries or fatalities | 50,000 – 1,500,000 |

Equipment Damage | Machines, materials | 10,000 – 200,000 |

Productivity Loss | Downtime, retraining | 10,000 – 500,000 |

Reputation & Insurance | Client loss, higher premiums | Long-term impact |

Total potential loss per serious incident: RM100,000 – RM1.5 million (or more)

8. Safety Is an Investment, Not a Cost

Employers are safeguarding their employees, property, and reputation when they make investments in safety training, appropriate tools, and frequent audits. “Every ringgit spent on safety saves several times more in prevented losses.” Businesses develop long-term sustainability, efficiency, and trust by cultivating a culture of safety.

Cost of Ignoring Safety Violations — and Why Training Pays

Ignoring safety violations is not just a compliance lapse: it converts latent risks into real, measurable costs such as financial, human, and reputational. Globally, work-related injuries and diseases remain alarmingly common: nearly 3 million workers die each year from occupational causes, and hundreds of millions suffer non-fatal injuries that impair productivity and quality of life.

Direct and indirect costs employers face

● Regulatory fines and penalties. Many jurisdictions impose heavy per-violation fines that rise with inflation and severity; willful or repeated violations can trigger six- or seven-figure penalties plus daily abatement fines. These penalties are immediate, public, and calculable.

● Medical, compensation and administrative costs. Treating injured workers, managing claims, and administering workers’ compensation generate substantial direct outlays. For example, national estimates place the annual cost of workplace injuries and illnesses in the tens to hundreds of billions of dollars.

● Productivity losses and hidden business costs. Absenteeism, reduced work quality (presenteeism), overtime for replacement labour, disrupted production schedules, and lost institutional knowledge all erode margins and delay projects. These indirect costs frequently exceed direct medical bills.

● Legal and settlement exposure. A safety incident can spawn litigation, class actions, and settlements that dwarf initial fines, sometimes driving businesses into insolvency. Publicized enforcement actions also attract additional scrutiny from regulators and insurers.

● Insurance and reputational damage. Claims history raises premiums; high-profile failures damage customer and investor confidence and hinder recruiting, partnerships, and access to capital. (See the regulatory, business-continuity and reputational consequences above.)

How workplace safety training reverses the equation

Well-designed safety training is not an expense but a risk-reduction investment. Decades of research show that targeted worker safety and health training improves safety knowledge, attitudes and safe behaviours, and is associated with reductions in unsafe acts and incidents when combined with supportive systems (supervision, enforcement, hazard controls). Systematic reviews and meta-analyses confirm training’s positive effect on knowledge, compliance and, in many cases, injury rates.

Practical bridge between violations and training

1. Map violations to training gaps. Use incident and inspection data to identify the most frequent violations (e.g., fall protection, lockout–tagout, machine guarding). Target training modules to those specific hazards so learning translates directly into safer behaviours.

2. Mix methods for retention. By combining classroom instruction, hands-on drills, toolbox talks, and competency assessments, the blended approach consistently produces better outcomes than

lecture-only formats.

3. Measure outcomes, not seat time. Track leading indicators (completion of hazard assessments,

near-miss reports, corrective actions closed) and lagging indicators (incident frequency, lost-time days, claim costs). Demonstrable reductions in these metrics convert safety investments into quantifiable ROI.

4. Embed safety into operations. Training must be reinforced by management commitment, documented procedures, routine inspections and a clear process for addressing violations promptly, only then will training fully mitigate the financial and human costs of non-compliance.

Who Should Join Workplace Safety Training?

Everyone who enters the workplace should receive workplace safety training, not just supervisors or safety officers. Every worker, regardless of role or background, helps to establish a secure and law-abiding workplace. Job titles shouldn't be a factor in accidents, and safety awareness shouldn't be either.

1. Employers and Management – The culture of the workplace is shaped by its leaders. Managers, directors, and employers need to be aware of the Occupational Safety and Health Act's (OSHA) 1994 legal requirements as well as how to incorporate safety procedures into day-to-day operations. Their involvement guarantees that safety regulations are implemented in all departments and are not just written documents. Compliance becomes ingrained in the company's identity when management is knowledgeable.

2. Supervisors and Team Leaders – When it comes to preventing accidents, supervisors are the first line of defense. They are in charge of keeping an eye on work-related activities, spotting potential risks, and making sure their teams adhere to safety procedures. They gain the ability to lead by example, identify dangerous situations early, and act quickly to address them thanks to training.

3. Technical and Operational Staff – On the job, workers who handle vehicles, machinery, tools, or hazardous materials are more vulnerable. These workers receive safety training that emphasizes incident reporting, emergency response, hazard identification, and safe equipment handling. Whether an accident happens or is avoided is directly influenced by their attentiveness and compliance with safety regulations.

4. Office and Administrative Employees – Slips, electrical hazards, and ergonomic injuries are commonplace, and accidents can occur even in office settings. Providing safety training to administrative and clerical staff fosters a culture in which everyone, from the front desk to the production floor, takes responsibility for workplace health.

5. New Hires and Contract Workers – Contract workers and new hires frequently don't know the company's safety protocols. Giving them on-the-spot training during orientation guarantees that safe procedures start right away, lowering the possibility of early-stage incidents brought on by uncertainty or inexperience.

Ignoring workplace safety is like saving pennies only to lose thousands later. Every year, avoidable workplace accidents in Malaysia cost companies and the country billions of ringgit in losses that could have been prevented with proactive safety management.

Establishing a safe workplace is not only morally required but also a wise business move that safeguards your employees, your brand, and your financial success.

Request for quotation today to start down the path to a safer, more compliant workplace and make safety your company's biggest investment.

Let workplace safety training serve as the cornerstone of your company's long-term success by empowering, educating, and protecting.